Metal Spinning

As metal spinning tooling is considerably cheaper than metal pressing tooling, short or long runs are cost effective. Complex shapes such as deep cones and venturis are produced at lower cost. Many projects, impossible or uneconomic using other metal forming methods are made possible by the metal spinning process. So why choose Metal Spinning? Learn about the metal spinning process and it's benifits.

Metal spinning is one of the oldest metal processes for the production of circular hollow metal components. For some time it has been kept in the background due to the difficulties in recruiting and training skilled labour. However, with the introduction of automation such as template control and CNC spinning machines, such issues have been resolved. Modern spinning methods provide solutions to forming from light (0.5mm) through to heavy gauge (8mm) sheet and pre formed (pressed) materials. Because of the low tooling costs, the metal spinning process is very often used for small to medium size batch production.

As metal spinning tooling is considerably cheaper than metal pressing tooling, short or long runs are cost effective. Complex shapes such as deep cones and venturis are produced at lower cost. Many projects, impossible or uneconomic using other metal forming methods are made possible by the metal spinning process. So why choose Metal Spinning? Learn about the metal spinning process and it's benifits.

Metal spinning is one of the oldest techniques for the forming and production of chipless, seamless circular hollow metal components. Because of the low tooling costs, the metal spinning process is often used for small to medium size batch production and where complicated component shapes are required.

For some time it has been kept in the background due to the difficulties in recruiting and training skilled labour. However, with the introduction of automation such as template control and CNC spinning machines, such issues have been resolved.

Modern spinning methods provide solutions to forming from light (0.5mm) through to heavy gauge (8mm) sheet and pre-formed (pressed) materials. For certain deformations it is superior to all other methods irrespective of quantities involved.

Complex shapes often require multiple stages of forming and some steels with limited formability (eg. Stainless steel) can also be formed in several operations involving interstage annealing.

Metal spinning has a wide application and can produce items such as lids, covers, rings, cones, cylinders and concave/convex parts. Parts with open ends such as bottles, spheres and jigs are also commonly produced.

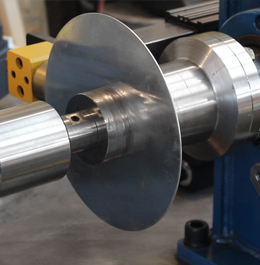

Flow forming, though sometimes thought of as a metal spinning process, is really a separate technology that requires a dedicated flow-forming machine. It involves forming rotationally symmetrical hollow parts. A blank or preform is clamped between the mandrel and tailstock and rotated. Metal is formed by localized radial pressure from (usually) three rollers applied simultaneously. The metal is made to flow and, in a single roller pass, assume the contour of the mandrel on the inside. Common applications include the thinning out of tubes and one-piece wheels.

Flow forming is an excellent method for forming nickel-cobalt-based super alloys, stainless steels, aluminium, brass, tantalum, columbium, titanium, and other heat-resistant steels. Flow forming produces parts that are cylindrical, conical, or contoured with precise control of desired wall thicknesses.

The key difference between flow forming and metal spinning is that spinning does reduce wall thickness of the starting blank; therefore spinning does not hold precise control of contours. Flow forming is based on a calculated reduction of the thickness of a starting blank or preform. The reduction is closely controlled, which results in precise wall thicknesses and accurate profiles of the final part. Flow forming is a cold forming process, which ensures the final part's controlled characteristics are to design with no distortion. The products manufactured with flow forming are more restricted—mainly to pipes and tubes with highly precise geometries, including their inside diameters and thicknesses.

Flow forming also strengthens the material, which presents some economic advantages. The process starts with thick, short preforms to obtain long, thinner-walled and precise final parts. Metal spinning uses only one, sometimes two, rollers, and only the roller tips control the work piece shape and thickness.

In flow forming, three or more rollers apply constant pressure against the material and mandrel throughout each stroke. Using parameters from the CNC, the machine controls the pressure and the work piece thickness at the forming rollers’ point of contact, all along the stroke. The result: Flow forming can produce a part with a highly accurate, uniform material thickness.

| Hemispheres | Shrouds | Food Containers |

| Venturies | Boilers | Cable Reels |

| Flanged Covers | Pots & Pans | Lamp Covers |

| Cones | Rocket Noses | Dairy Equipment |

| Dished Ends | Strainers | Air Heaters |

| Funnels | Urns | Buckets |

| Stepped Parts | Sinks | Centrifuge Covers |

| Parabolas | Cylinders | Centrifuge Dishes |

| Ducts | Tubes | Lids |

Commonly Metal Spun Materials Include:

1191 Beitel Road | Robertville

Randburg | Gauteng | ZA

P.O.Box 2974 | Cresta | Johannesburg | Gauteng | 2118

South Africa

Tel: + 27 (0)11 474 2644/5/6